Home Energy Water Work Economy Solution Politics Team Product Recycling Cars Ships Aircrafts Promotion

World Pollution Air Weather Violence Women Weapons Psychology Plants Animals Food Peace Faith Imprint

Energy

Parabolic mirror 1901

Since 1900 we could have set up an international solar energy network, all necessary technical elements were available.

I prefer thinking that we should had have done this.![]()

Please also take a look at the pages on this topic: https://www.inwogro.de

Electricity and hydrogen are the energy forms of a new post-fossil period

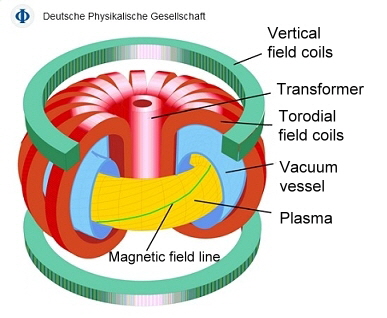

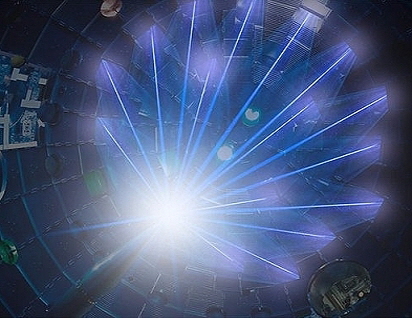

With the sun, we have the largest fusion reactor right under our noses, and some countries are constantly trying to replicate it on Earth. I ask myself, "Why?" We already have one; it works perfectly, and we have vast areas of land in the world's deserts available to utilize this fusion reactor.

We urgently need more energy, it must be cheap and not produce CO2.

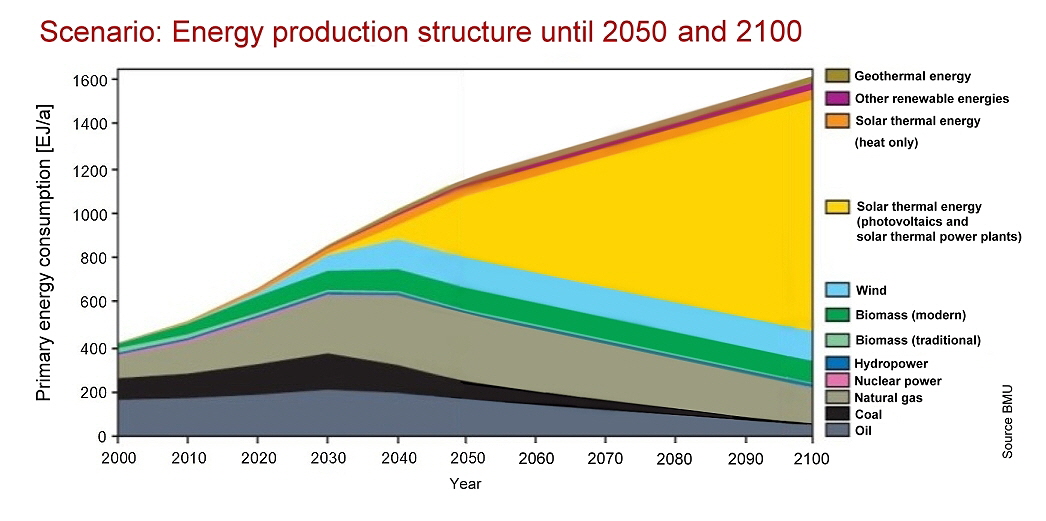

Future energy demand will rise sharply over the next 75 years, and there's no way we can meet this extreme demand with photovoltaics and wind turbines alone.

This completed graphic from the BMU (Federal Ministry for the Environment, Climate Protection, Nature Conservation and Nuclear Safety of the Federal Republic of Germany) clearly demonstrates this: Without solar thermal power plants in the desert, it won't work, and wind power will probably not be able to expand any further in the near future. However, the BMU still foresees the use of fossil fuels in 2100, and we must move away from them as quickly as possible.

Hydrogen fusion reactors, a completely different fantasy

I am often asked about fusion reactors and I would like to answer:

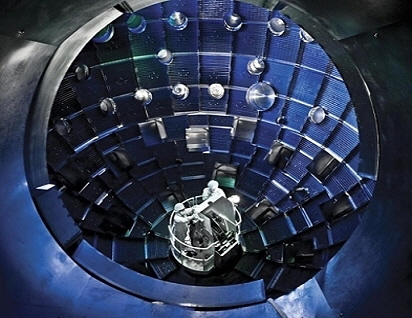

Example: ITER (International Thermonuclear Experimental Reactor) and NIF 2009 (National Ignition Facility)

A huge area is being built for the ITER research reactor alone. It won't be finished until 2027 at the earliest, will cost around 15 billion euros, will have operating costs of around 30-50 billion euros, and will never produce any energy. The first usable results aren't expected for another 50 years; by then, 300 tons of moderately radioactive waste will have been produced, the temporary disposal of which will cost at least 40 billion euros, while dismantling the facility and final disposal of the waste will cost 100-200 billion euros. So, in the best-case scenario, we have to reckon with costs of 185 billion euros (taxpayers' money) for the eventual discovery in 2077 that these reactors are incapable of producing more energy than they put into them, because it's still not clear whether the whole thing will ever work.

The latest report concerns: The 3.5 billion dollar NIF 2009: It doesn't work! The laser-based wonder reactor which recently achieved an alleged breakthrough - for the first time a laboratory experiment produced more energy than was put into it - has ultimately also been a flop. The operators say the fusion project is struggling with a host of difficulties; the predictions based on initial tests with smaller lasers and computer simulations were too optimistic. The plant does reach the temperature of 50 million degrees required for ignition, and hydrogen nuclei are already fusing to form helium. But because the fuel capsules break apart too early, they cannot ignite completely. And if and when that will happen is not yet foreseeable. And even if it does happen, it would still not be the final breakthrough for a laser-based fusion power plant. After all, it would then have to be investigated as to whether the whole thing could even be converted into a commercially viable technology.

My father always used to say: Why do it the easy way when you can do it the hard way?

For comparison: NOOR:

The world's largest solar thermal power plant cost € 2.2 billion, took three years to build, delivered 580 megawatts of power immediately upon completion, and the sun doesn't generate any operating costs. Only minimal maintenance costs are incurred, and disposal and dismantling costs are also relatively low. These can easily be covered from the reserves of the plant's generous profits.

Source: Welt.de

Hydrogen and its application as an energy store

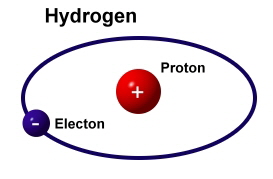

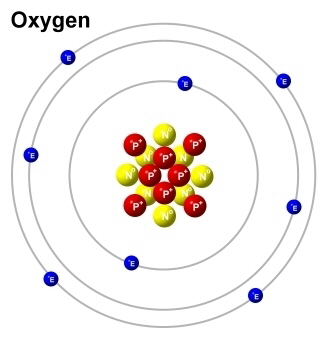

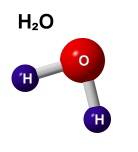

There's plenty of hydrogen on Earth, but two atoms of it are always hanging around with one oxygen atom. Or, the hydrogen is combusted in conjunction with oxygen. We call this partnership water. So, we need to separate them again.

![]()

![]()

The force that drives the hydrogen atom towards oxygen is the electron.

It is the same electron that drives machines and generates light; it makes computers work, powers refrigerators, and is the basis for almost everything that makes our lives easier. Without electrons, we would look pretty old. We cannot create electrons directly, but we can move them. This is the basis of our electrical energy. Through movement, we can generate an excess of electrons, which we call voltage. With this voltage (U), measured in volts, it is then possible to force the electrons to work for us and produce power (P), expressed in watts. Their path through a conductor and the resistance we serve is called current flow (I), the quantity of which we measure in amperes. If we now give the hydrogen its electron back, it separates from the oxygen atom, and we can use the energy stored in the hydrogen by burning the hydrogen again. To do this, we first have to generate some power. We have to build lots of power plants, because this conversion of electrical energy into hydrogen and back from hydrogen into electrical energy involves significant losses. In this back and forth, we lose a full 85% to 87% of the energy. Another 5% to 10% is lost through transmission lines, meaning we have to build approximately 90% to 97% more power plants than if we were to use the electrical energy directly.

Experimental result: Conversion of electrical energy into hydrogen – hydrogen into electrical energy:

Only 13-15% of the electrical energy taken from the grid could be fed back into the grid; 85% and 87% of the electrical energy was lost during the conversion of electrical energy into hydrogen and the reconversion of hydrogen into electrical energy, respectively, in the 2003 experiment at the FTZ in Büsum.

Storing electrical energy in hydrogen is therefore a very, very lossy storage option.

Electrolyzers: Let's first look at the conversion of electrical energy into hydrogen. Everyone is probably familiar with this process from chemistry class; it's called electrolysis:

Electrolyser model Source: Davidlfritz

Nice. Isn't it? Hydrogen absorbs electrons and is reduced in the process, while oxygen releases electrons and is oxidized in the process. In between, a membrane allows only the tiny ion cores of the hydrogen to pass through, thus separating the two atoms. The efficiency is 75%-80%.

The fuel cell:

How a polymer electrolyte fuel cell works Source: bbs-brv.de

It also goes back. Hydrogen releases electrons. On this side, there's an excess of electrons, which then rush around the outside through the resistor. On the other side, there's a shortage of electrons. Here, the oxygen absorbs electrons and is reduced in the process. The hydrogen's protons pass through a membrane, which they can only pass through without electrons, to the other side. There, the hydrogen then recombines with the oxygen, producing water and heat.

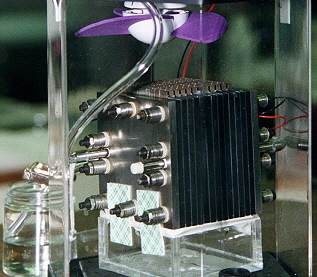

![]()

Single fuel cell and a fuel cell stack

Both systems are always processed in stacks in order to get more performance.

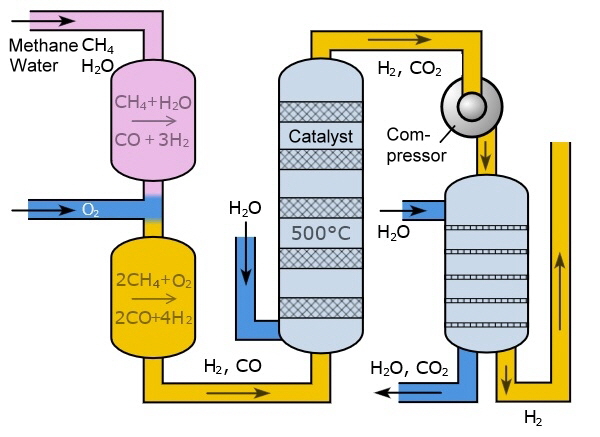

Reformation:

A tree does similar things, by the way. However, it uses solar energy to convert water and carbon dioxide (CO2) from the air into three main components: cellulose, hemicellulose and lignin, which are hydrocarbon compounds and we call it wood. It can't use the oxygen and so it simply excretes it. Most other plants do the same, and this is how we can breathe. I think that's a great thing. Aren't plants amazing living beings? I mean, after all, we owe them our lives. And not only that. Next time you get in your car, please remember that you're only driving because the gas tank contains the squashed body parts of our tree's grandparents. This stuff, usually petrol or diesel, belongs to the group of hydrocarbons. Because we need oxygen, a lot of CO2 is produced. That's the stuff that's causing us so many problems right now.

However, we can also produce pure hydrogen directly from these hydrocarbon compounds; this process is called reforming. However, in addition to hydrogen, this process also produces significant amounts of carbon monoxide (CO), carbon dioxide (CO2), and nitrogen. The conversion efficiency (natural gas to hydrogen) is only approximately 60 to 70%.

Hydrogen needs something very important and that is water

If we want to generate electrical energy in deserts, there is generally very little water there, and even if we transport it there, it wouldn't make much sense to produce the hydrogen in these deserts, transport it to ports via tanks using transport vehicles such as trucks or trains, and then ship it to other distant ports, and then transport it from there, possibly via high-pressure pipelines or again by truck or train, to consumers. The length of this explanation alone is a headache.

It would be better to have the electrical energy generated in the world's deserts available everywhere in an international energy network and, together with an international water network, to produce the hydrogen locally, where it is needed, and deliver it to consumers in small, local low-pressure networks. Larger consumers could use their own generating stations.

Adapted hydrogen stations, located in the immediate vicinity of consumers, and small low-pressure networks for nearby consumers, villages, and urban settlements, represent the most sensible form of use. Short supply routes guarantee a truly loss-free and green use of hydrogen.

This is precisely why we need the international energy and water network!

But where do we get the water from? From the sea!

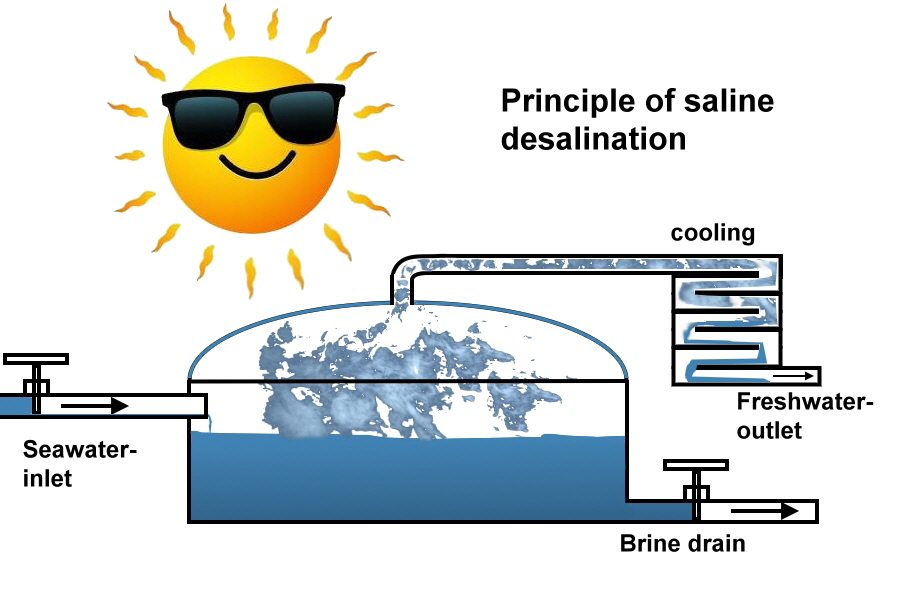

Desalination plants

However, we are no longer allowed to use reverse osmosis systems, but rather evaporated salt works. We want to use this technology on the coasts of warm zones because we heat the salty water with solar energy on relatively flat stainless steel sheets encased in glass. The water evaporates, and we collect the pure water vapor, cool it, and transfer the water to tanks. This technology reduces CO2 emissions by 1,400 percent compared to reverse osmosis.

We would need hardly any external energy and, above all, no chemicals. This process produces little non-toxic brine or even no wastewater at all, because salt is extracted simultaneously. Furthermore, various minerals such as calcium, magnesium, sodium, chloride, and even lithium can be extracted from this brine through nanofiltration.

In order to produce drinking water, however, we have to add important minerals back to the water, so some of the extracted minerals are used again. If the water is used to produce hydrogen, irrigate fields, or replenish groundwater reservoirs, mineralization may not be necessary because no minerals are needed, natural fertilizer is added, or the water absorbs minerals from the soil. Incidentally, sea salt is of high quality and very sought after. Rock salt from mines would then hardly be used anymore; chefs all over the world swear by sea salt. There are already special desalination plants that produce sea salt foam, known as Espuma de Sal. The waiting time for this salt is months. The same applies to Flor de Sal, the flower of salt, a layer that forms on top of the brine in the last basin and is skimmed off by hand. The industrial production of fertilizer from sea salt instead of rock salt is possible in principle, since both essentially contain sodium chloride. Sea salt can have a higher mineral content, so for fertilizer production, sea salt would have to be processed and processed into a product suitable for agriculture, similar to what happens with rock salt.

The process itself isn't anything new or breathtaking, but rather the same as how salt was once produced on land from mines and at sea in large, shallow basins. The water evaporated, and the salt remained. On land, energy was required, but at sea, the sun did it. Here, we combine the pan technique of mine salt production with the evaporation technique of basins at sea, and with the technique of liquor brewers by collecting, cooling, and utilizing the evaporating water.

Osmosis technology, a membrane that filters minerals, salts, and other dissolved substances from the water, can ensure that our water is free of minerals and limescale, making it ideal for hydrogen production. These osmosis systems would then also be located on-site, close to the hydrogen production facility.

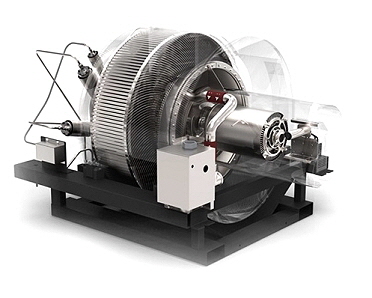

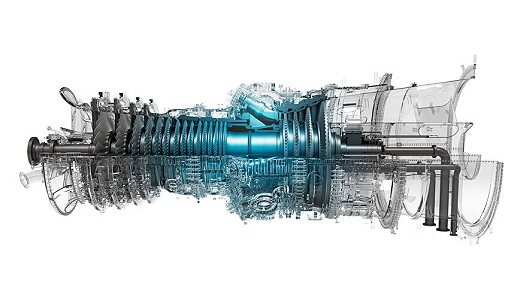

The hydrogen turbine

We now have hydrogen and could convert it back into electrical energy. The hydrogen turbine for stationary use drives a generator, generating electrical energy. This way, electrical energy could be stored in the form of hydrogen, albeit with losses.

The hydrogen turbine could also be used in aircraft to generate thrust. New turbines are currently being researched, but hydrogen is difficult to store; it requires huge tanks that must be specially insulated. Therefore, hydrogen cannot be used for long-haul flights; the tanks to store enough hydrogen would simply be too large.

![]()

Micro and power turbines

Other drive types:

There is, of course, also a hydrogen combustion engine based on the Otto cycle principle. Its efficiency is around 35%, making it better than a gasoline engine, which is around 28% efficient, and worse than a diesel engine, which runs at approximately 40% efficiency. Lubricating oil consumption results in traces of carbon dioxide, carbon monoxide, and hydrocarbons in the exhaust. However, its performance is lower than that of gasoline engines, and there are a number of other problems that make a hydrogen combustion engine very expensive and complicated to solve. The efficiency of a hydrogen combustion engine is significantly lower than that of fuel cell vehicles and electric cars with a traction battery, which can achieve efficiency of up to 90%. In this respect, the electric motor is simply unbeatable.

Conclusion:

However, when converted via a fuel cell, only 13%-15% of the original power of the electrical energy invested is achieved, which actually makes the fuel cell the absolute loser.

With all this "hydrogen discussion," we should also consider what would happen if there were 200,000 potential hydrogen bombs in the air (a busy day in the air) and 1.6 billion on the ground.

Of course, the producers claim the gas tanks are safe, but gas transports explode practically all the time; the most recent one just happened in the Zhejiang province of China, killing 19 and injuring 172.

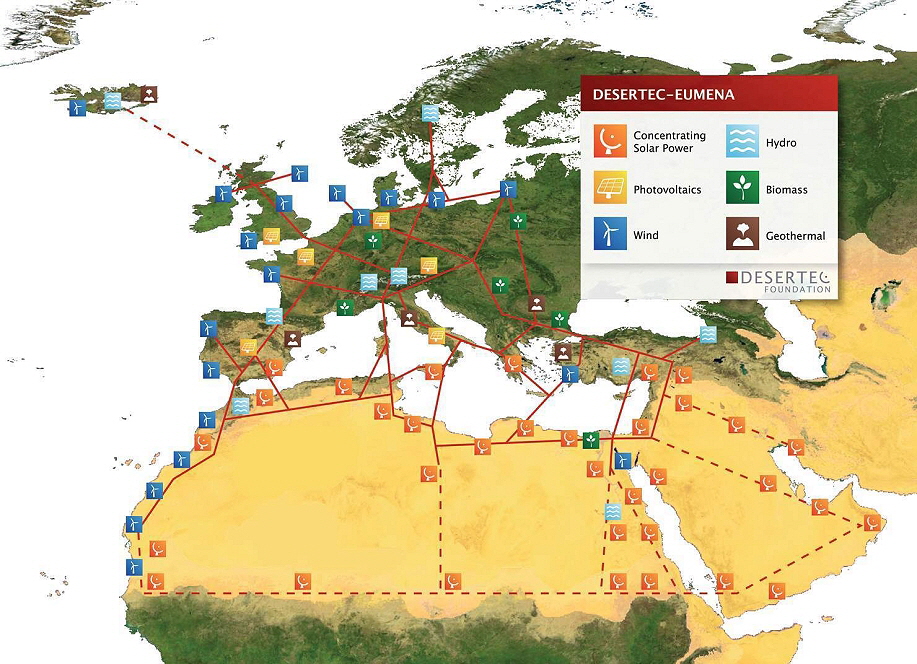

The Desertec Project

When I first wrote my papers in 2003, the very idea of phasing out combustion engines and replacing them with electric vehicles was considered almost unconstitutional. As recently as 2018, a politician postulated that diesel would never disappear. My related idea of building a network consisting primarily of solar thermal power plants also met with little enthusiasm. But in 2010, the idea of transporting desert electricity to Europe via high-voltage direct current lines was finally taken up, and the Desertec Industrial Initiative was born. By 2050, at least 15% of European electricity demand was to be met by power from the Sahara. The Desertec Foundation played the first leading role, while the second was a consortium of industry, energy companies, and banks.

But soon, a dispute arose: one group wanted to export energy immediately, while the other wanted to fully supply the MENA (Middle East and North Africa) countries first. Then, in 2013, the project was called off. They say they're continuing to work on it, but so far, nothing has happened. Companies that have left the MENA region believe it is one of the most politically unstable in the world, unstable, with deficits in legal certainty, and a changing economic environment, and that politics is the first priority here. There were some attempts to do this, but the talk quickly faded into the ground and we'll deal with it another time.

Unfortunately, the greatest weakness of our heads of state and business is their dominance, dogmatism, and contentiousness.

There was also a shift in perspective on technology. Regarding short-term energy costs, solar thermal power plants, which dominated the planning for Desertec solar technology, were overtaken by the cumbersome and ecologically questionable photovoltaics. Here, short-term profits once again dominated, contrary to all reason, because solar thermal power plants are much more economical in the long term. Long-term calculations are simply not taught at business schools.

The energy production costs of a PV system in Germany, depending on the location, are between 8 and 14 cents/kWh. The costs of generating energy in solar thermal power plants in southern Spain are between 14 and 20 cents/kWh. The fact that a solar thermal system lasts four times longer and is then very easy to recycle is irrelevant. This makes it clear: Easy money rules the world, contrary to all reason.

The authors of a Fraunhofer study on the production costs of electricity from renewable sources comment on their findings: "Due to the significant cost reductions in PV systems in recent years, PV power plants at the same location have a "short-term" cost advantage over CSP power plants."CSP = Concentrated Solar Power; Solar Thermal Power Plants; PV = Photovoltaics

Now, due to the recent situation—temperatures have risen faster than expected in recent years, citizens are slowly becoming afraid and demanding an energy transition—the issue is now being discussed again, and the BMU, I hope, is slowly starting to do the math. At least it has clearly been established that the energy transition won't really progress without solar thermal energy.

Dimensions:

To give you an idea of the dimensions of the energy transition, here's a quick calculation:

Global energy consumption is currently at 590 exajoules per year (source: BMWI), which equates to 163,889 TWh per year.

As an example: The "Noor" solar thermal power plant in Quarzazate, Morocco: Output 580 MWh, 580 MWh x 24 (hours per day) x 365 (days per year) = 5,080,800 MWh or 5.09 Twh/a 163,889 TWh/a ÷ 5.09 TWh/a = ~ 32,198 Noor-type power plants would theoretically be needed constantly to meet current energy demand. It may not seem like a lot, but this is the number that must be constantly connected to the grid and able to supply energy. Solar power plants supply, at best, 12-13.5 hours of full energy per day. Since these plants have storage, they can also generate energy at night, but only for 3 hours.

Ensuring an optimal supply would be easier, more efficient, and more cost-effective via an international energy network in all the deserts of the world. If everyone builds for themselves, a lot of excess capacity has to be provided, which drives up costs.

4 MW wind turbines might only produce an average annual output of 1.6-1.8 MW, while larger turbines with 8 MW would produce twice that. But even if we could build even larger turbines, the space required would be too large for this planet, and even if we could meet half of the demand with PV systems, the cost, the resulting waste, and the demand for rare earths would be so great that we would have to use up all available resources, and then there still wouldn't be enough minerals to adequately meet global demand. This alone makes individual energy supply via wind energy and photovoltaics practically impossible; it won't work without solar thermal power plants in the deserts.

So why wait until 2050? We should really focus on making the most of this opportunity. I think that's the only way we can get out of the valley of tears we're currently in.

On the situation in the so-called MENA region

Since Europe and America discovered this area, we have mercilessly exploited it. Poor people simply fight for what they have. After 1945, the USA commissioned a study to determine why fascism arose in Germany, and they concluded that it was primarily the poor economic conditions that were responsible. And right-wing forces all over the world are once again hyperactive, gaining new supporters and voters almost daily.

If we show up there again, build power plants where no locals can find work, let the region continue to dry up, and don't take care of the people, they will continue to fight for what they have and see us as just another nuisance. Since they know us from experience, they are unlikely to be particularly receptive to us.

We need a good plan

We should really present a plan there that primarily advances the local population. Existing business relationships should also be adjusted accordingly. Everything we enjoy in terms of consumption is thanks to the fact that people there live in huts we wouldn't even go into. For hundreds of years we have been dragging everything valuable out of these countries and forcing the people there to live like dogs because they have to work for us. In Chile people are dying of thirst because German companies are growing avocados there and thus robbing the surrounding areas of groundwater. In Africa people are dying because they are burning our electronic waste to extract copper and other metals in order to survive. All of this must come to an end quickly.

If we change capitalism so that it can function successfully, defused and under strict supervision, if we recognize that this capitalism, as it is now, is eating its own host and completely paralyzing us, if we then begin to do what we know is the only right thing, because it is sensible and intelligent, then we will come together with both the still and again troubled areas of the world. We would also quickly do business with the so-called socialists, I'm pretty sure of that.

Because the division in almost all countries between right and left is all caused, and again, by capitalism, with its insane mass production and its consequences, just like global warming.

If we don’t make it

Instead of being able to act as is actually necessary, but always only according to whether it brings quick money for a few or not, in the hope of living off what is left for us, we will miss the change and only take action when it is too late.

On the other hand

With the international electrical energy and water network project, we could eliminate unemployment and migration at the same time. If we then bring sensible products to market that last a hundred years and are then easily recycled, we could reduce energy demand in the long term to a level we can sustainably afford. With a fiscal policy based on dynamic interest rates, returns, and dividends, we would create peace, stability, and planning security. Annoying inflation would be a thing of the past, and prices would remain stable forever. Likewise, we would no longer need an ever-expanding economy that litters, pollutes, and heats up the earth. We would live safely and peacefully, without haste and problems, with a permanently stable and clean economy.

Thermosolar energy

The solution for our future

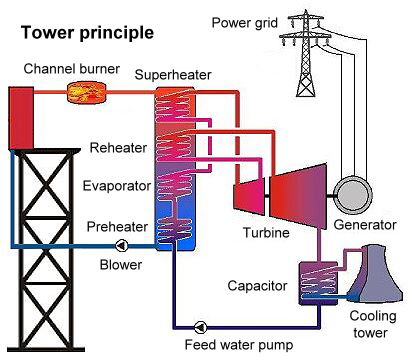

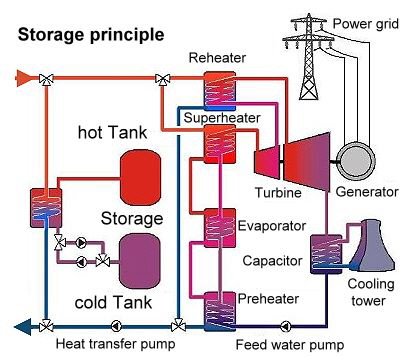

In the thermosolar or also named solar thermal energy generation, a medium is heated with the help of the sun. This medium expands or transforms into a gaseous state, driving a turbine, which in turn drives a generator that then produces the desired energy. Another method is the Stirling engine. This is powered solely by heat, eliminating any liquid, and the directly connected generator also produces the desired energy.

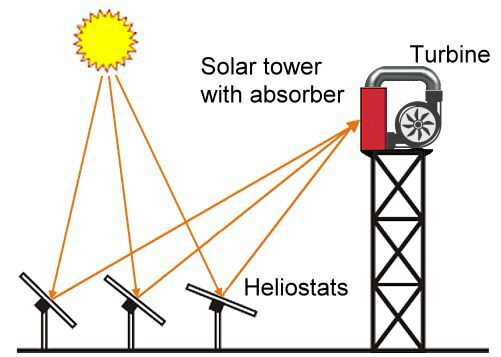

The Solar-Tower

A large number of mirrors, so-called heliostats, direct the sun's rays onto a point on a tower. This point is heated to up to 1,000 °C, and the resulting vaporized liquid then drives a large generator via a turbine, delivering a large amount of electrical energy to a central location. This is the advantage of this technology. A disadvantage is the large number of heliostats, each of which must be controlled individually via complicated computer programs, gigantic computers with thousands of control outputs. Since each heliostat requires two motors, a considerable amount of technology and cabling is required. This presents significant maintenance challenges and significantly reduces the lifespan of the system. One advantage is that the enormous heat is stored in liquids and thus in insulated tanks, meaning it can be used to generate energy for some time even at night. The entire system is essentially like a giant parabolic mirror.

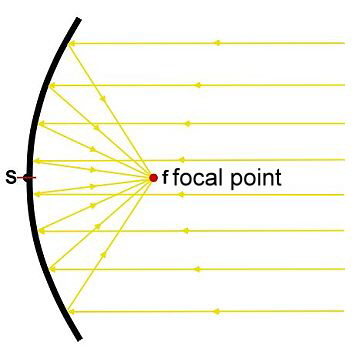

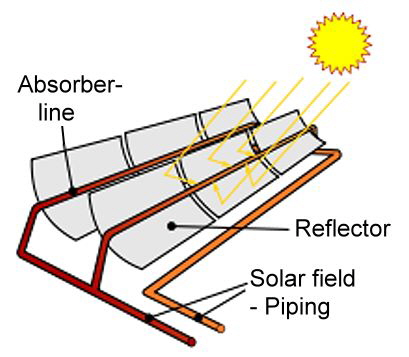

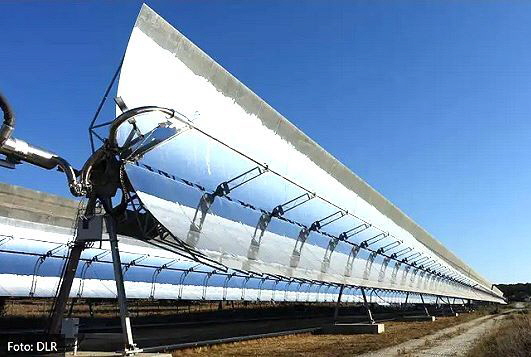

The parabolic trough

This technology is based on long parabolic troughs with an absorber line installed at their focal point. A liquid is heated in this line, which then expands and can be used to drive a turbine. The troughs can be arranged in series or parallel using lines, so the optimal temperature can be achieved in every season. Since all of the troughs in the system are connected to one another via a solar field line, a central generator can be operated, just like in a tower, which then provides large amounts of energy centrally. A disadvantage of this technology is that the long troughs can only be adjusted along one axis and so cannot always be optimally aligned towards the sun, which reduces the efficiency. Another advantage here is that the heat in the liquid can be stored in tanks so that it can also be used for a while at night.

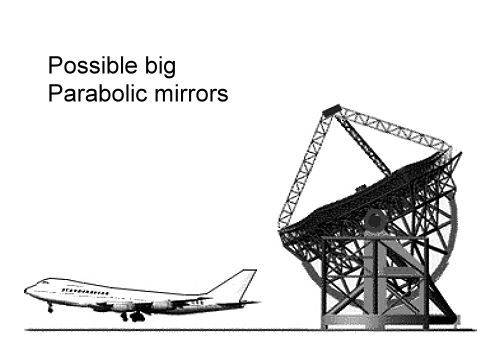

The round parabolic mirror

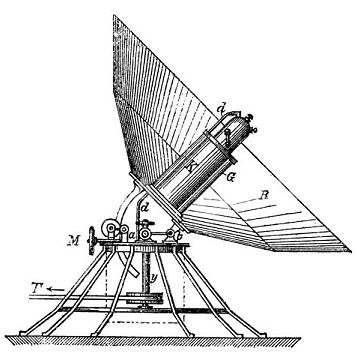

This technology is by far the oldest form of converting solar energy into electrical energy. It is also the most efficient method. The mirrors can be moved along the X and Y axes, ensuring they are always optimally aligned with the sun. Controlling a mirror array is extremely simple, as the mirrors primarily move parallel on one axis, while the second axis can be operated statically. The first image shows a steam boiler mirror by Augustin Mouchot from 1878 that powered a small generator, and the second image shows a mirror with a Stirling engine and generator, which can also directly generate electrical energy. These systems can also heat liquids, and the arrays can then be used to centrally power large generators, and these liquids can also be temporarily stored in tanks. These mirrors can be used in small, medium, and very large systems. Developing large mirrors is no problem, as they already exist as parabolic antennas that can be easily reconfigured.

The big advantages

The main advantages are the enormous potential for savings in rare earths and critical metals, especially since large parabolic mirrors are largely made of metal, and the motors needed to align the mirrors can be large and do not require neodymium or similar materials.

Another advantage is the control system; theoretically, it is possible to control an entire array of parabolic mirrors (dishes) with a notebook.

The entire technology is very simple; if the models are standardized and limited to three or four models, the parts could be manufactured anywhere in the world.

The biggest advantage, however, is the long lifespan of such a structure, up to over a hundred years, with proper maintenance and care.

Such mirrors can also be easily recycled later, and the material can be reused.

Another very significant advantage of such an international energy and water network project is the market boost it would create, especially in regions from which many people have to flee because they see no future for themselves and their families.

I cannot see all these positive effects with other production methods.

Wind energy use

Conclusion:

Wind turbines and the like cost a lot, take up a lot of space, produce little power, and generate a lot of waste that's difficult to dispose of. Even with the most modern technology, only the tiny generator and the gearbox can be recycled. The concrete base, the column, and the blades are and will remain hazardous waste. A wind turbine only lasts a maximum of 25 years. Given the megalomaniac expansion plans, this translates into an irresponsible amount of waste.

Wind power is unreliable! Without wind, there's no energy.

Offshore and onshore turbines are changing the climate and causing lasting damage to nature.

By comparison: A solar power plant in the desert generates a great deal of power every day, takes up 90% less space, and is located in regions where it can't cause damage. It lasts for over 100 years and can be recycled up to 90%.

Problems of wind energy in detail:

Human use of wind energy is an intervention in the ecosystem. Energy cannot be created, only converted. All natural energy is used 100 percent by nature without human intervention, and any intervention disrupts the original energetic balance. Wind turbines, in particular, are disruptive in many ways.

Wind turbines are fog machines

Wind turbines create wake turbulence that persists for miles. Turbines positioned in water, in particular, lift the moist ground air and mix it with the colder upper air layer, causing the water to condense into fine droplets that then coalesce to form real clouds. The opposite effect occurs at night, only much more pronounced, when the cold, moist air sinks to the ground and the warmer layers settle above it. The suction force of the wind turbines pulls the cold, moist air from the ground and mixes it with the warmer air layers above it, creating a uniform temperature, and the important morning dew on the ground is eliminated.

Over time, the soil around the plants dries out.

Furthermore, wind turbines significantly disrupt the natural movement of air. The air is slowed down by the wind turbines and turbulence increases. This atmospheric disturbance then lasts for ten to one hundred kilometers and in the case of large turbines, particularly in the planned extreme expansion, these also influence the major atmospheric currents, which can lead to phenomena such as prolonged dryness or even supra-regional droughts, as well as heavy rainfall events. On land, the evaporating soil moisture is drawn off the ground, carried upwards and thus dewatered from the entire surrounding area. In the sea, water vapor is produced which then moves uncontrollably in large clouds and can suddenly settle somewhere. If electromobility actually becomes widespread and industry switches completely to electrical energy and hydrogen, the demand for electricity would increase enormously and if we were to cover all of this mainly with wind turbines, the land consumption would be simply gigantic and the associated rise in temperature and weather turbulence would also be very high.

Wind turbines destroy forests

Large-scale wind turbine construction is currently underway in Norway and Sweden. I am certain that the natural habitat there, with its reindeer and thriving forests that have existed for thousands of years, will be significantly disturbed and thus destroyed. The forest areas will dry out and disrupt the forest's natural growth. Wind turbines undoubtedly have a particularly damaging impact on forests. First, the forest, as a CO2 sink and water reservoir, is decimated by logging. Erosion and leaching of the former forest soil, as well as silting, lead to faster water runoff, and there is a threat of desertification of the cleared areas. Added to this is the underground soil sealing caused by the reinforced concrete foundations, which weigh several thousand tons and are more than three meters thick. The moist soil above it dries out, and the water cannot infiltrate and participate in groundwater regeneration. The same effect occurs on the compacted access roads and assembly sites. The climate-regulating effect of the forest is reduced overall, and its natural resistance to extreme weather is diminished. It is obvious that the area of the driest soils roughly coincides with the spatial distribution of most wind turbines.

Wind turbines are heaters

How does a wind turbine actually work? Well, from a physical perspective, the wind blows along the blade, creating positive pressure on one side and negative pressure on the opposite side. This moves the blade in one direction and, if a generator is connected to the axle to which the blades are attached, performs work. However, it doesn't work as smoothly as the lovely descriptions always make it sound: "Wind in, electrical energy out." Instead, it's exactly what happens when a skater skates on ice. Pressure and friction are created, and this creates heat, which melts the ice, forming a film of water on which you can glide.

A wind turbine also creates pressure and friction when the wind overcomes the resistance of the blades and the wind turbine does its work. This heats the air behind the wind turbine by around 0.2°C, depending on the conditions. Part of the converted energy is also immediately released into the environment via the waste heat from generators, gears and transformer stations. In extensive American studies: "Climatic impacts of wind power", Lee Miller and David Keith from Harvard University researched the effects of onshore wind farms in the USA in 2018 and came to the conclusion that with the current level of electricity supply in the USA from wind power, the temperature over the continental surface of the USA would rise by up to 2.4°C.

Lots of space need, high resource consumption, little energy

Wind farms have only a tenth of the energy density of solar thermal systems, and even then, only for a very limited time. This means that wind farm systems require 90% more space than solar thermal systems to generate the same amount of energy.

Resource consumption is also 90% greater:

Wind turbines contain vast amounts of copper and rare earth elements; up to 25 tons of copper and up to 3 tons of rare earth elements are found in one wind turbine. A medium-sized wind turbine, including infrastructure, requires up to 400 tons of copper and 45 tons of rare earth elements such as praseodymium, dysprosium, terbium, and neodymium. A wind turbine with a capacity of 10 megawatts requires 2 tons of neodymium alone. In addition to GRP, balsa wood is also used in newer rotor blades, meaning that one rotor blade contains approximately 50 trees. This means that an entire wind turbine requires approximately 150 trees. The nacelle housing is made of aluminum, of which up to 350 tons are needed per wind turbine.

Without these raw materials, the so-called energy transition will fail. With this extreme consumption and the expanded plans, copper and rare earths in particular will become scarce.

This is precisely why recycling, especially of rare earths, is extremely important. But once the turbines are in place, it is very difficult, for example, to dig the cables out of the ground every thirty years, dismantle the entire infrastructure, and recycle them. Metals are still only shredded and sorted, resulting in various material mixtures rather than pure metals. There isn't even any thought of manually dismantling the motors and generators and separating the material. The situation is even worse with rare earths. Currently, laboratories are still busy with extremely trivial melting experiments, and there is no evidence of this in industry yet. At best, the gold is extracted from electronics, while the rest burns in the smelting furnace, producing high levels of pollutants. The balsa wood in the latest rotor blades isn't recyclable.

Huge reinforced concrete bases, enormous steel or concrete columns, massive rotors, vast quantities of copper, aluminum, and rare earths, and so little energy.

This means we can't counter the danger posed by this massive global warming, and failure isn't an option. It's only possible together and only with the most effective energy generation, and that is generating electricity with solar power plants in the world's deserts.

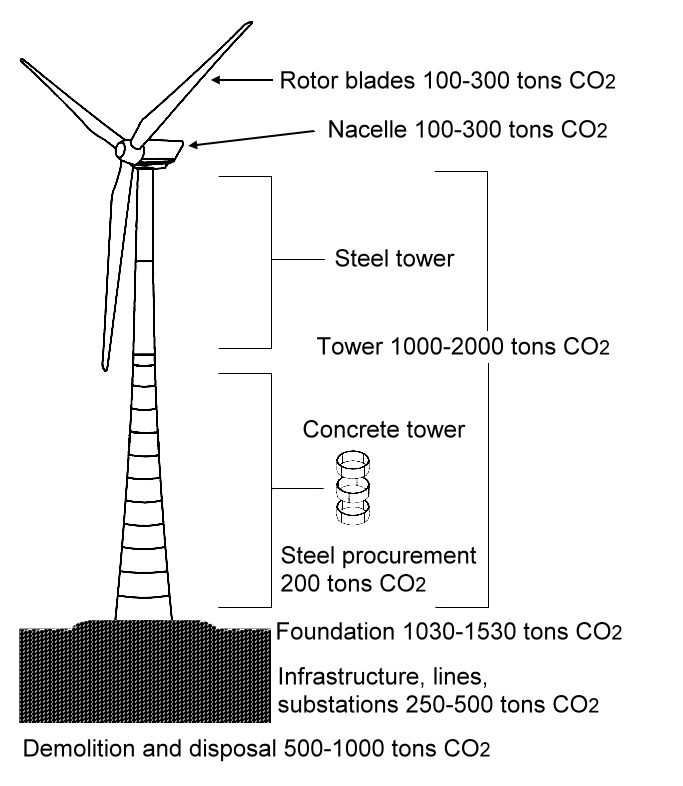

Wind turbine waste and carbon dioxide

Not only do wind turbines leave behind a huge amount of waste that's extremely difficult to dispose of, their production also generates vast amounts of carbon dioxide. After 20-25 years, a wind turbine must be dismantled for safety reasons.

A 7-megawatt wind turbine is said to save around 6,790 tons of CO2 over its lifetime. Is that true? Let's take a closer look.

Currently, around 600 kg of CO2 are produced per m³ of reinforced concrete. For a wind turbine base for a 7 MW turbine, you need around 1,680 cubic meters of concrete and 200 tons of steel, or 1,008 tons of CO2. Just over 200 truckloads of concrete are transported every day from a factory 50-100 km away. This also costs CO2. Just under 1 kg per km averages out to about 22 tons more. Now we're already at 1,030 tons of CO2. As I said, that's just for the base. Let's take a look at the steel column: around 150-250 meters high, 20-30 m in diameter, steel up to 1 m thick, and 120-200 tons of steel, smelted, rolled, coiled, and welded in segments. Or with a hybrid tower, one half is made of reinforced concrete tubes and only the rest is a steel tower. Around 1,300-1,600 cubic metres of concrete and 180-200 tonnes of steel are used here. We can therefore safely assume that a wind turbine tower produces another 1,000-2,000 tonnes of CO2, depending on its design and height. The iron ore comes primarily from Brazil. In addition to this, there is transport via heavy oil transport ship from Brazil to Germany. That means at least another 200 tonnes of CO2 and various toxins. The blades are made of carbon fibre reinforced composites (CFRP), carbon fibres glued together with highly toxic synthetic resin. After they have died, they are shredded, mixed with fire aid and burned in concrete plants. The cement industry is now to be obliged to at least use CO2 capture systems, but there will still be no cleanup of the toxins. There are plans to recover the carbon fibres in the future, but so far this has only been lip service. There are no concrete test results yet. So for now, it remains the same: When using three massive CFRP blades, another 100-300 tons of CO2 are emitted over the lifetime of the turbines, both during production and destruction. The nacelle, with its control motors for the blades, the massive gearbox, and the generator, isn't exactly a children's birthday party where everything is free. This, too, produces another 100-300 tons of CO2. All in all, a wind turbine produces an average of 3,130 tons of CO2, not including the dismantling of the turbine (blasting) and the disposal of the remains. That's still another 500-1,000 tons of CO2. Added to that is the construction of the infrastructure, offshore installation, the power lines, and the substations, which add up to another 250-500 tons of CO2. So we are now at the well-intentioned figure of approximately 4,500 tons of CO2 that a large wind turbine produces in its lifetime, saving a total of 6,790 tons of CO2, so the bottom line is a saving of unfortunately only 2,290 tons of CO2.

However, this will add another 4,500 tons of CO2 to the atmosphere, and this will only end when the industry has completely converted and 100% recycling is finally possible. The problem is that 10,000 large wind turbines will add an additional 45 million tons of CO2 to the atmosphere, which will then remain in the atmosphere for around 1,000 years. After 1,000 years, around 15 to 40 percent of this will still be in the atmosphere. However, the entire breakdown process takes several hundred thousand years. So we must—NOT could or should—we absolutely must take the path with the lowest emissions, and that is producing thermosolar power plants where emission-free energy already exists, and we must operate these plants for at least 100 years or longer.

The biggest problem is the wings

Fiberglass-reinforced plastics (GRP) cannot be stored in landfills because they do not decompose. They cannot be burned either because they barely burn. Therefore, they are converted into a substitute fuel using combustion engines and then burned with other materials, which significantly reduces the value of wind turbines as a source of green energy. The smoke generated during this process must be cleaned in extremely complex systems, and the resulting highly toxic dust and an equally toxic liquid remain, which must then be disposed of in hazardous waste landfills.

But the concrete bases and columns of wind turbines, which weigh several tons, are also a major source of CO2. These bases can no longer be used. They must be crushed and are then only suitable as a secondary product in road construction.

It is still unclear how many billions of tons of this waste will accumulate worldwide in the next few years, but it is certain that the majority of it cannot be recycled or reused.

Photovoltaics

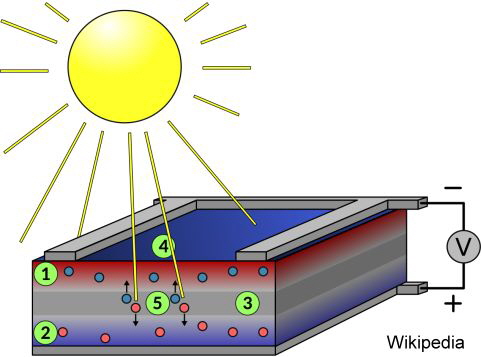

Photovoltaic Function (Thin-Film Solar Cell)

1) The upper silicon layer is interspersed with phosphorus atoms, where there is an excess of electrons. These electrons are freely mobile.

2) The lower silicon layer is interspersed with boron atoms, where there is a shortage of electrons. These holes are freely mobile.

3) A strong electric field is created in the transition layer.

4) Light enters the transition layer, and electrons are excited.

5) The light energy then creates new charge carriers, and a voltage is generated. The electrons then move through the layers that make up the solar panel to the battery.

Photovoltaics is not a thermosolar, but a purely solar form of energy generation. This means that electrical energy is generated not through heat, but only through light. The solar panels don't require heat; in fact, frost is not a problem at all for photovoltaic systems. It doesn't damage the material and can have a positive effect on yields. Cold can even increase the efficiency of the modules. This is due to silicon, the material from which most photovoltaic modules are made. This is why photovoltaics is also suitable for use in colder regions, but the requirements and risks are enormous.

Conclusion:

The costs of manufacturing and subsequent disposal are enormous and diminish the benefits of such systems. The performance and value of a photovoltaic system deteriorate rapidly. After ten years, a PV system is worth only half as much. After 25-30 years, the systems and their components are scrap and must be replaced.

The production and disposal of solar panels and the necessary electrical and electronic components, especially batteries, requires a great deal of energy, which unfortunately is currently still produced from up to 90% fossil fuels. Recycling and the entire logistics required for this technology also only function using fossil fuels. The combustion of the residues from a photovoltaic system produces significant amounts of CO2 and toxins. Hazardous waste landfills are required to store the residual material. This, of course, significantly reduces the actual production of climate-neutral energy.

It would therefore be logical to limit the use of photovoltaics until the issues of climate-neutral production and recycling of materials have been resolved.

In detail:

The production of photovoltaic modules is a complex process that ranges from the extraction of silicon from quartz sand to the final testing of the finished module. To produce monocrystalline solar cells, silicon is melted and purified. From this melt, a rod is then drawn, forming a uniform crystal lattice, a so-called single crystal or monocrystal. These ingots are then cut into thin wafers and processed into solar cells. A distinction is made between polycrystalline and monocrystalline solar cells, as well as thin-film cells. Melting silicon is necessary for all types. This process requires a lot of heat and, with today's energy mix, releases a large amount of CO2.

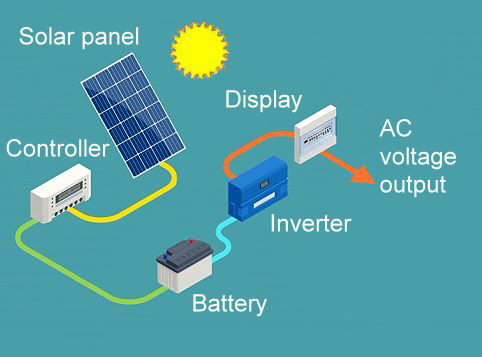

Enormous amount of additional technology required

A photovoltaic system requires a lot of electronic and electrical equipment to make electrical energy usable for the home. The direct current from these panels is low and the panels do not generate much power. If they were overloaded they would get hot and start to burn. The energy therefore has to be stored in batteries in order to reach a certain power level. This storage must be controlled by a device so that the battery is not overcharged and starts to burn. The direct current from the battery must then be converted into a higher alternating current in an inverter, which in turn must be monitored so that the battery is not overloaded and starts to burn. The necessary batteries in particular leave a considerable negative ecological footprint. Today's battery recycling technology also devours vast quantities of energy, which unfortunately still comes from fossil fuels.

The biggest problem with photovoltaics is their design, which limits the lifespan of the panels. Immediately after commissioning, solar cells begin to decline in performance. This normal process, triggered by electron movement, essentially causes atoms to disintegrate due to a lack of energy, is called degradation and causes a power loss of up to 80% in solar modules after 25-30 years of operation. After just ten years, the value of a photovoltaic system is halved. After 25-30 years of operation, the system must be replaced.

Where to put the gigantic amounts of waste?

According to reports, China will generate the largest share of PV waste by 2050, at 13.5 million tons. The United States follows with 7.5 million tons, Japan with 6.5 million tons, and India with 4.5 million tons. Germany ranks fifth and could accumulate approximately 4.4 million tons of end-of-life PV modules by 2050. Europe's largest solar module recycling plant recycles just about 4,000 tons per year.

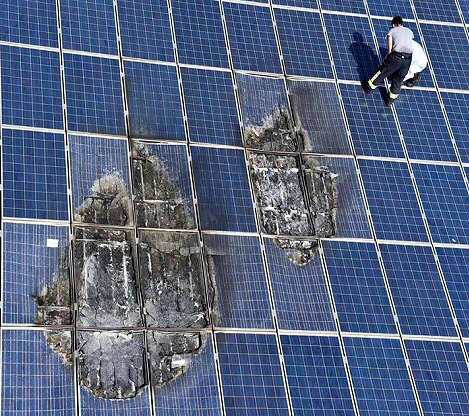

Reliability, safety, service life and damage

Many a PV system owner has been ripped out of his savings dreams because PV systems are sometimes very sensitive and can even catch fire. Especially in our times, they can be as big as hailstones like walnuts or even oranges. PV panels can also hardly withstand

Hail, Storm and fire damage to PV fields

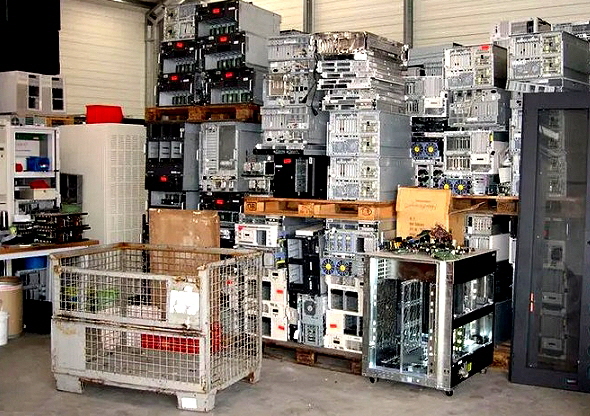

Recycling

The energy used for recycling is currently still generated from up to 90% fossil fuels. The necessary logistics still rely almost exclusively on fossil fuels. The entire process causes more environmental damage than benefit.

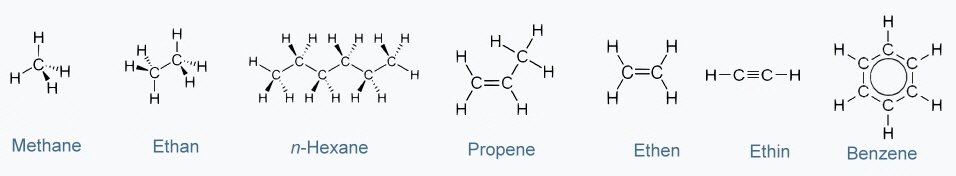

Another major disadvantage is that the material, which is manufactured in a complex process consisting of silicon, copper, silver, indium, cadmium, lead, selenium, and tin (depending on the type), cannot be separated and recycled back into the manufacturing process. The plastics are converted into gases such as methane, propane, and butane, which are then burned again, producing CO2. The recycling rate is only around 70-90%. The trick with so-called recycling is the glass, which makes up around 60-70% of the weight, and the frames around 10-20%. This makes it quite easy to achieve a recycling rate of 70-90%. There is no need to remove the material bound up in the cell. The leftovers, around 10-30%, end up in hazardous waste landfills. Due to the truly gigantic amounts of waste that are to be expected in the future, 10-30% of this is 4-12 million tons of toxic material that will end up in landfills in the first wave alone and will not be recycled.

So we produce hazardous waste, at great expense, using a great deal of energy, sometimes with rare metals that we take from the sea or the ground, destroying nature in the process and then simply throwing it away.

Many more raw materials could be reused

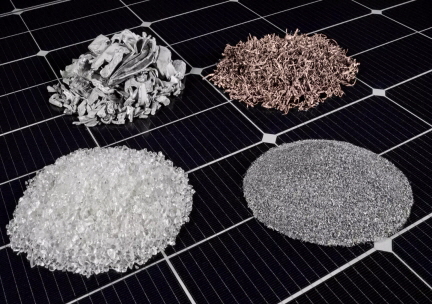

In a recycling process, the solar panels are disassembled, meaning shredded. Glass, aluminum, silicon, plastic, and copper are mechanically separated and, unfortunately, only partially processed into new solar panels.

Say goodbye to romantic ideas of recycling

Image 1) Glass, frame, and photovoltaic film are separated. Image 2) The films are shredded. Image 3) What remains is a scrap mixture.

Image 4) The frames are pressed into cubes . Image 5) The final step is completed in a purely mechanical separation line. Image 6) What remains is aluminum, copper, glass, and silicon, and depending on the machine, also silicone or plastic.

Silver, indium, cadmium, lead, selenium, and tin cannot yet be separated. Because chemical separation is not yet possible or not profitable enough, these materials end up in hazardous waste landfills or are incinerated.

Therefore, it is extremely important to finally research the chemical separation and recycling of such materials.

For clear understanding, I am not against photovoltaics per se, but against something being simply produced without knowing exactly how it can be turned back into what it was before. Instead, highly toxic waste is usually dumped into our living space and then, despite knowing exactly how millions of tons of highly toxic hazardous waste will be generated and lying around somewhere, production simply continues. That is really irresponsible. The most irresponsible thing, however, is that the legislators allow producers to simply produce something WITHOUT taking responsibility for their products. It is clear to me: whoever wants to produce something must take their product back after use and completely dismantle it into its original raw materials. Throwing it into nature is simply not acceptable. Only natural materials may be stored in nature. There must also be No hazardous waste landfills.

Burning toxic substances is also completely unacceptable. The stuff will eventually come down somewhere and poison people, animals, or the soil.

Dismantling it into its original raw materials is possible. Even the recycling and complete irradiation of nuclear fuel elements is possible.

Of course, that doesn't generate any money; it costs money. It may cost so much that a product can no longer be sold because it's too expensive.

But that's no argument for committing a crime such as intentional bodily harm. The introduction of toxins into the habitat of living beings is nothing less than the creation of natural disasters through unnecessary global warming.

It's more of an argument for not producing the product at all, or for suspending production until the problems with the product have been resolved.

One solution would be to systematically increase the price of raw materials through taxation, as this measure would make recycling lucrative.

This would help counteract the greed for this rare and very limited material and enrich the respective state coffers. This way, future generations would also have some of these important rare earths and critical metals left over.

Production in the desert

It would be even better to limit the consumption of rare earths and critical metals by generating electricity using simple systems in the world's deserts. This, too, is very expensive and requires a lot of money.

The only question that arises is: How does the money get into the desert?

So the question of how the money gets into the desert does not arise. With consistent planning and, of course, an equally sustainable implementation of certain plans, the developed cells attract more and more investors.

The nice thing about it is that there is almost free energy here, on which you can then build up corresponding returns. Because the pure energy is always given by the sun. It doesn't have to be dug around dangerous and dirty in the earth, the deserts or the workers are not contaminated with oil, it is almost too good to be true. But let's think about the USA for a moment. Of course one will say that was for the most part fertile land which one could exploit accordingly and that brought these enormous growth rates.

But in this project we have the sun and the resulting energy that compensates us for this and creates fertility. Because energy is clearly also matter and vice versa. All you have to do is take the appropriate measures and we have been able to do that quite well since the 1900 century.

One of these measures is to invest in kind in a fund, above a certain volume you will go with the thing on the stock exchanges of the respective countries.

Please also take a look at the pages on this topic: https://www.inwogro.de

To the top ![]()

![]()

![]()

Home Energy Water Work Economy Solution Politics Team Product Recycling Cars Ships Aircrafts Promotion

World Pollution Air Weather Violence Women Weapons Psychology Plants Animals Food Peace Faith Imprint